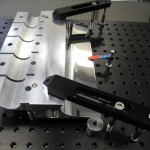

There were several parts to this reverse engineering project, only the reflectors are pictured. The flash lamp reflectors have an involute curve where the X & Y axis have different equations governing the curve. This shape allows the energy of the flashlamp, including that energy emitted from the back side, to be focused onto a target plane. The reflectors are then stacked two high opposing each other with the flashlamp positioned at the focal point.

While the customer’s device was down for maintenance, they had the opportunity to investigate why the performance of their device did not perform as well as expected. They delivered the original reflectors and 30 year old drawings (they were actually “real” blue prints), to have us inspect them. We found that the original reflectors were not compliant to the print specifications.

Following their confirmation of our findings, we were asked to produce new reflectors. New models were created, and the new reflectors were fabricated with a 2A finish on the reflector surface. First articles were performed to provide evidence of dimensional and finish conformance.

With the new reflectors installed the devices output was considerably higher and another customer was highly satisfied.