A customer was restoring a special version of a 1925 Buick and asked if we would be able to produce a new distributer body, timing plate, shoulder bolts, and the bushings for the distributor shaft.

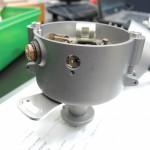

The original diecast part was frozen inside the housing which mounts to the motor, and several chunks had fallen off which thankfully the owner still had. After several rounds of cleaning, the part had to be broken in two to remove it from the main housing. Additionally there is a was a timing plate riveted to the bottom of the main body which had to be removed.

The parts were measured by our inspection department, initially on the CMM, but confirmation measurements were also made on the surface plate due to the poor condition of the part. The measurements were quite challenging.

The data was fed to engineering, were models and drawings were created. Following customer approval, the job was rolled out onto the shop floor. After multiple fabricating operations, the parts were tumbled for a uniform matt appearance.

We found an anodize color that was a very close match to the original diecast color. Several test pieces were run at different coating thickness to see how thick we needed to have the coating for a good color match and still maintain dimensional tolerances. Following anodize we installed many of the original components for a fitment check.

We made the timing plate out of stainless (the original was steel) for a nice clean look that wouldn’t corrode and turned the bushings out of Oilite.

The customer installed the new distributor and the car ran on the first try.