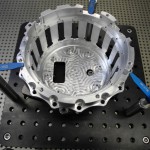

Our inspection department has three labs, each with an array of top notch measuring equipment (see capabilities tab above) enabling us to drive manufacturing and certify your product. Some examples of the types of equipment utilized include:

- White Light Interferometer with air ride table

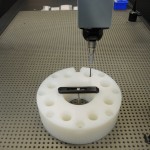

- Multiple CMM’s

- Multiple Vision Systems (OGP & Keyence)

- High Accuracy Micrometers

- Laser Micrometer

- Hardness Tester

The inspection labs have sealed doors with independent temperature and humidity controls, data loggers are employed in the inspection labs, and throughout the manufacturing plants, to record temperatures and humidity. This aids in making manufacturing decisions on very tight tolerance parts and is required for the instruments that are calibrated in-house.

The use of quality inspection gear extends to the shop floor as well. We carry a full line of Mitutoyo hand tools and height gages. We also maintain a full line of thread gages for inch/metric screw thread, NPT, NPTF, BSPP, BSPT and helicoil threads.

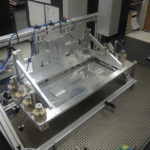

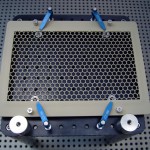

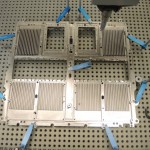

In addition to certifying product produced in house, we also perform contract inspection. From single part inspections to turnkey inspection, where we supply a fixture and a CMM program, we have the capability to meet your quality requirements.

Our inspectors are certified as Welding Inspector Specialists in accordance with AWS B5.2