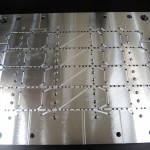

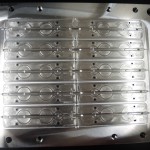

Milling is at the heart of operations for Oakdale Precision. We have new Okuma horizontal mills with pallet changers, new Mazak vertical mills with laser tool setters, probes, and 4th axis capability.

Nearly all our machinists are setup machinists that have the technical capability to take a job from start to finish, and produce a product efficiently to drive costs down.

We maintain a vast selection of materials on hand, both metals and plastics, to support quick turn jobs. We commonly mill:

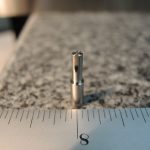

- Aluminum, Brass, Bronze, and Copper

- Stainless, various steels, and Titanium

- PEEK, ULTEM, Polycarbonate, Delrin, and ABS.

Our customers constantly give praise about our surface finishes compared with that our competition!